Our design know-how ensures reliable production with short lead times. In the production chain of your product, mastering assembly techniques is one of Votat’s added values to deliver a finished or semi-finished product. Thanks to our experience and our machine park, we offer a wide range of assembly techniques to adapt to your needs and constraints.

Welding

To meet your need for permanent assembly, we master many welding techniques: TIG, MIG, MAG, by spot, with the wheel and solder. The choice is made according to your technical constraints. Regardless of the process used, the resulting weld is a joint that retains the same properties as the material of the assembled parts.

We are equipped with three spot welders, an oxyacetylene welding station and an electric welding station.

Riveting

In order to guarantee you a permanent assembly that cannot be dismantled, we adapt the riveting mode to the needs of your product. The assembly is done cold, by drilling the parts to be assembled.

Clinching

Our teams master the technique of clinching to assemble sheets and profiles by deformation without adding material. We offer you a high quality of result in terms of strength and rigidity. Ideal for thin sheets, this process has the advantage of not deteriorating the surface condition of metals. It is reliable and ensures final profitability and without impact on the environment.

Crimping

By mechanically cold assembling two elements by deformation, without adding material, we meet your needs for clean, safe, aesthetic and durable results of your final product.

Tapping

Our teams are able to meet your needs for machining a thread inside a bore. Discharge tapping consists of printing the part in the shape of the tap, thus ensuring the correct surface finish, static strength and high dynamics of tapping.

Our workshops include a tapper and a multi-spindle tapping unit.

Products made by VOTAT

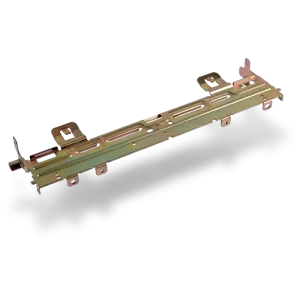

Special closure system

Fixing foot